2017-08-01

Controlling dynamic and protecting drive systems

Manufacturer RINGSPANN presents itself as a versatile machine tool supplier at the EMO 2017

When it comes to the issues of drive technology and clamping technology, RINGSPANN belongs to the core group of premium suppliers in the field of international machine tool engineering. The worldwide active company provides high-quality components and systems in both sectors that can help machine tool manufacturers to significantly increase the process safety, performance capability and customer-orientation of their machines. At this year’s EMO in Hannover (18.-23.9.2017) RINGSPANN presents overload clutches, shaft-hub-connections and brakes, as well as force limiters, clamping units and entire precision clamping fixtures in Hall 3.

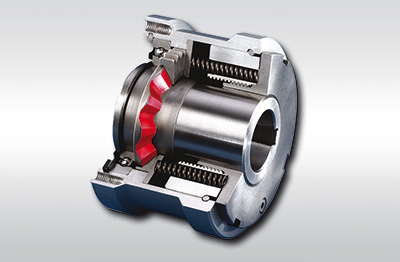

Bad Homburg, August 2017. – In addition to shafts, bearings and motors, manufacturer RINGSPANN offers a wide range of essential components for the safe and reliable operation of the main and auxiliary drives of modern tool machines and processing centres. The company’s form-fit SIKUMAT® torque limiters and RIMOSTAT® friction torque limiters connected via friction lining, for example, are in use all over the world. As an overload protection device for machine tool drives and spindles, they are available ready to install in various versions for different limit torques (0.5 – 10,000 Nm) and speed ranges (1,000 – 13,000 min-1). The bi-directional acting RINGSPANN force limiters for disengaging forces of 3,600 – 140,000 Nm, meanwhile, are specially designed for the overload protection of push rods und drawbars. Overload clutches can also be found at the company’s EMO trade fair stand in Hall 3 (Booth C40).

Brakes for all axles

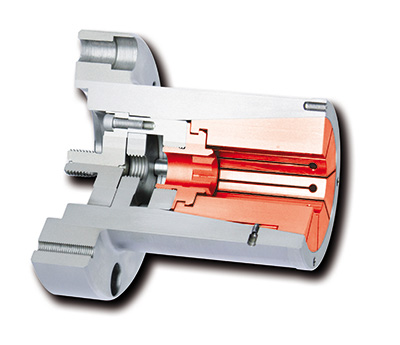

At the EMO, RINGSPANN will additionally be showcasing exhibits from its range of industrial brakes. On its way to becoming a one-stop supplier for drive technology components, the company has – among other things - been significantly expanding its range of brakes over the last couple of months. RINGSPANN’s compact electromagnetic disc brakes, which can be used for braking, stopping and emergency stopping gravity-loaded and drive axles as well as linear axles and rail guides, are hereby particularly relevant for the manufacturers of tool machines and processing centres. The latest generation of RINGSPANN electrical brakes have thus proven to be a real attraction at the EMO. That is down to the fact that these electronically controllable disc brakes from the EV and EH series convince thanks to their lean installations dimensions, low weight (from 6.5 kg), numerous Industry 4.0 features (e.g. sensory monitoring) and high energy efficiency. In the holding phase, they manage with extremely low power consumptions – the smallest models only require 10 watts. In the field of electrical brakes, RINGSPANN currently offers 16 basic types in four frame sizes with clamping forces of 1,800 to 24,000 N. In total – i.e. across all technologies – the industrial brakes portfolio of the company spans some 60 series with brake torques ranging from 0.5 to 600.000 Nm! Also included in the exhibition range at the EMO were RINGSPANN’s hydraulic and pneumatic clamping units, which are suitable for the secure holding of axial positions of moving bars.

Connections for all shafts

A further focus of RINGSPANN’s presence at the EMO was shaft-hub-connections connected via friction lining. This area, too, was only recently expanded by numerous new series, meaning that the entire range of the company now encompasses torques of 0,16 Nm to 4,225,000 Nm. What is particularly interesting for engineers, purchasers and product developers in the machine tool industry, however, is the fact that all technically relevant variants of shaft-hub-connections can be found at RINGSPANN: externally clamping shrink discs for a play-free connection of hollow shafts or hubs on shafts, internally clamping cone clamping elements for the frictional connection of hubs on shafts, internally clamping star discs for applications with frequent switching between clamping and release and star spring washers for the compensatory tolerance of ball bearings. Clamping systems for the mounting of torque motors on machine shafts connected via friction lining equally form part of this product group of RINGSPANN – they can also be viewed at the EMO in Hannover.

Transmission in all situations

One RINGSPANN product group that is sure to surprise many EMO attendees is the range of push-pull cable systems from the company’s subsidiary RINGSPANN RCS. These mechanical controlling and operating elements, similar to the classic Bowden cable, are currently experiencing a renaissance in mechanical engineering, and that is because they offer the engineer a both flexible and reliable solution for the location-independent transmission of axial forces from a fixed point of origin to a remote or even mobile component. Several tool machine manufacturers use these “remote control systems” as a cost-efficient option to implement manual adjustment functions across metre-long, winding distances – for example for the angular positioning of saw blades, cutting or grinding discs. In these applications, the premium-processed cable systems of RINGSPANN RCS have proven themselves to be extremely safe and reliable operating elements, with whose help significant forces of several thousand N can be transferred with great smoothness of movement in both pull and push directions.

Precision for all cases

Manufacturers of tool machines for lathing, milling, grinding, gearing and balancing who are looking to supply their customers with fully equipped processing centres should also pay a visit to RINGSPANN at the EMO. That is because there is hardly a company that has been engaged as intensively with the development and manufacturer of precision clamping fixtures for the mechanical processing of workpieces with cylindrical internal and external surfaces as RINGSPANN has been for almost 80 years now. An overview of the current portfolio is provided by the company’s clamping fixtures division at the EMO booth in Hall 3. Largely standardised, complete clamping fixtures are now the focus of attention. They are offered in nine versions, so mechanical engineers – depending on the needs of their customers – can select four flange chucks and flange mandrels respectively in the construction forms bonded disc, tapper collet, taper sleeve or flat element, as well as a taper collet centre mandrel. With true running accuracies of ≤ 10 µm, these complete systems are an ideal solution for many demanding machining processes. RINGSPANN will also be exhibiting its clamping elements for the customer-specific self-designing, as well as clamping chucks and mandrels for the realisation of individual clamping fixtures. And, as an absolute technology highlight, RINGSPANN will present the new expanding sleeve mandrel mandrel HDDS. This new development for gearing technology and fine machining is a highly precise and economically attractive alternative to hydraulic expanding clamping tools. It stands out thanks to a true running accuracy of ≤ 5 µm, can take workpieces with bores of up to tolerance class IT10 and reduces the costs for the necessary feeding and positioning technology in fully automated operation.