2019-11-18

Innovative smart solutions for the drive train

RINGSPANN is implementing ready-to-install combination solutions consisting of shaft couplings and overload clutches

With international commitment and great consistency, RINGSPANN continues to pursue its development towards being a one-stop supplier of high-quality components for industrial drive technology. The company’s ability to equip machine and plant manufacturers in many industries with innovative smart solutions for the drive train is also growing. A current example of this are ready-to-install “packages” consisting of shaft couplings and overload protection, which simplify the work of designers and significantly reduce assembly work.

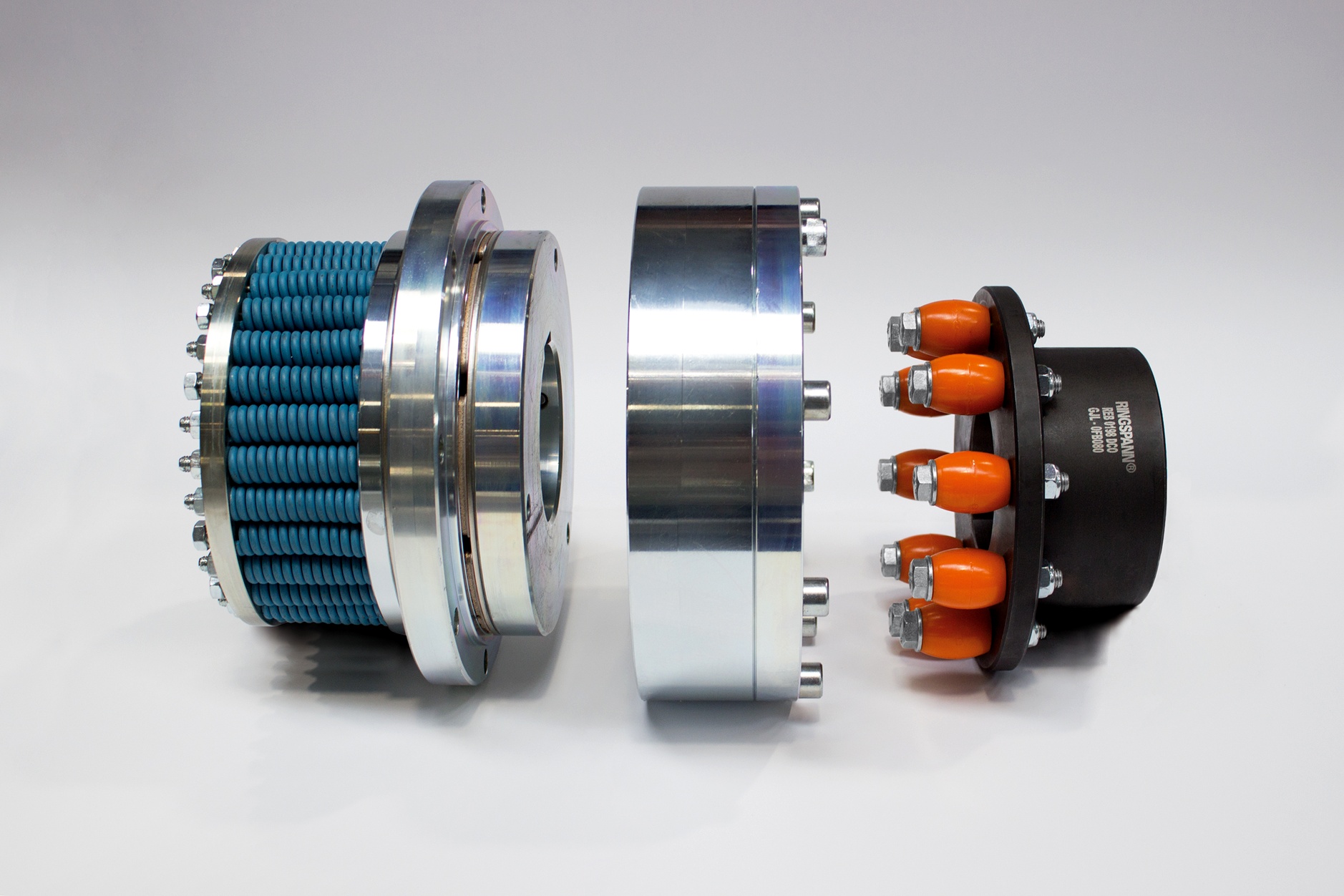

Bad Homburg, November 2019. – By founding further subsidiaries and consistently expanding its portfolio, RINGSPANN has recently considerably strengthened its position as an international one-stop supplier of drive components for machine and plant construction. Thanks in particular to targeted expansions in all product groups, the company is now able to offer its customers a wide range of innovative smart solutions that significantly reduce the time and cost involved in both engineering and assembly. A good example of this is the combination of elastic shaft couplings with high-temperature resistant overload clutches. Martin Schneweis, product manager responsible for RINGSPANN’s shaft couplings, specifies: “In this specific case, we combine size REB 0198 DCO pin couplings, which were only recently added to our product range, with our successful type RSHD 250E special RIMOSTAT® friction torque limiters. This resulted in an innovative package solution for the drive train of a screening drum in a new plant for bulk material processing.” While the pin and bush coupling compensates for the misalignment between the shafts of the drive train and dampens operational shocks and vibrations, the RIMOSTAT® friction torque limiter serves as overload protection when blocking the screen drum – caused, for example, by overloading.

Components from two product groups

The elastic pin and bush couplings from the REB…DCO series are part of RINGSPANN’s wide range of non-switchable shaft couplings, which also includes rigid flange couplings and clamping clutches, torsionally stiff disc couplings and jaw couplings, along with a host of other types. The pin and bush couplings operate lubricant-free and are suitable for vertical or horizontal mounting. They are also available as ATEX variants and are frequently installed in the drive trains of fluid technology and logistics systems – for example in the drives of pumps, fans and belt conveyors.

RINGSPANN’s RHSD series RIMOSTAT® friction torque limiters, on the other hand, are considered classics among overload clutches and are used all over the world. They are designed for slipping torques of up to 60,000 Nm and have highly wear-resistant sinter friction linings. Such a friction torque limiter achieves maximum service life, is absolutely corrosion resistant and can also be equipped with electronic speed monitoring. The RIMOSTAT® RSHD friction torque limiters are in good company with the numerous friction torque limiter series of the SIKUMAT® family in RINGSPANN’s overload clutch range.

Tailor-made functional unit

As a ready-to-install smart solution, the package consisting of the 13 kg REB 0198 DCO pin and bush coupling and the 39 kg RIMOSTAT® friction torque limiter RSHD 250E special forms a customer-oriented compensation and safety solution. RINGSPANN’s product manager Martin Schneweis explains: “With regards to the interaction of the technical parameters of its two components, the unit is precisely tailored to its application in the drive system of the screen drum. The pin and bush coupling is designed for a maximum speed of 3,400 1/min and – depending on the damping elements used – has nominal torques ranging between 1,240 Nm and 3,150 Nm; the friction torque limiter, meanwhile, is defined for speeds of up to 2,100 1/min and its slipping torque is adjustable from 1,200 Nm to 6,000 Nm.”

The example described is representative of many other smart solutions that RINGSPANN is able to implement thanks to its broad – and growing – product range. The current catalogues on shaft couplings and overload clutches alone give an idea of the potential synergies. Both catalogues are already available in the latest issues 2019-2020 for free download.